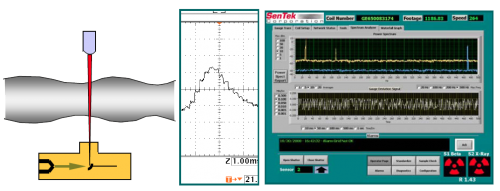

Higher frequency vibration harmonics resulting from undesired interaction between the work rolls and backup rolls can cause very narrow but significant thickness variations in the rolled product. These thickness variations are often too narrow for conventional thickness gauges to detect and report. Over the past several years, SenTek has developed a set of tools and techniques for detecting, reporting and analyzing these thickness variations.

In a modern, high-speed rolling mill, the gauge and the mill control form a large feedback loop that can make it very difficult to determine whether the gauge device is accurately measuring the thickness variations. Our very high speed X-ray gauge with a micro-focus beam combined with a spectrum analyzer built in to the gauge device will detect and report even very narrow bands of thickness variations. A heavy-duty accelerometer in the gauge device will display the vibration frequencies and allow the user to determine which frequencies are due to actual thickness variations, roll eccentricity problems, and those that are due to vibration. These tools are available as part of our gauge systems or as stand-alone rolling mill tools and services.