SenTek’s latest revision of our successful Coat Weight Gauge features several improvements and enhancements. The system is now capable of two-component measurement and includes a coating mass control feature.

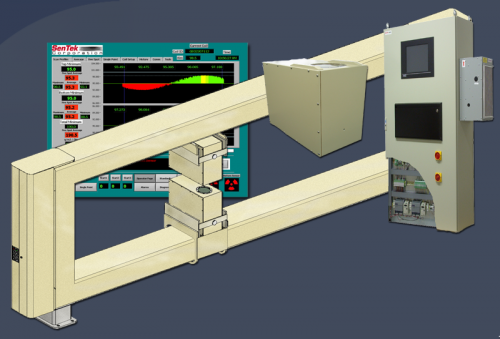

Our sensors and scanners are built to withstand the rough environment and harsh chemicals of the hot dip and electro-plate galvanizing line. High-speed signal processing and precision drive components work together to measure and map the coating across the strip fast and accurately.

SenTek is currently able to offer two-component measurement in the Al-Zn, Zn-Fe, Zn-Ni, Zn-Cr, and Cr-Al families of coating mass products.

SenTek’s Coat Weight Gauge system can be installed onto existing O-frames/scanners that we refurbish as part of the system conversion, or we provide a complete gauge scanner built on our own complete O-frame Scanner.

Our Coating Weight Gauges are built with the SenTek 1000 Gauge Electronics Platform. High-speed measurement, pin-point diagnostics, coil reports, trending, and network interfaces are just some of the great features of our Model 1000 Gauge Electronics Platform.

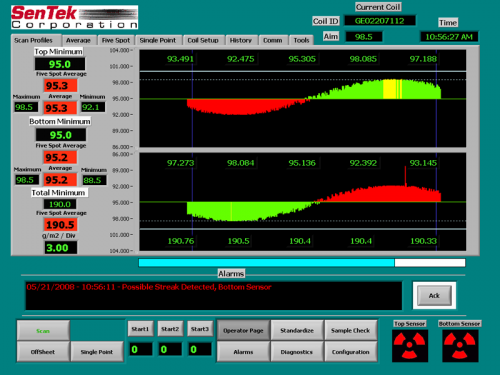

High Resolution Profile Displays

SenTek’s 1000 Coat Weight Gauge system features multiple operator screens with high-resolution profile displays and a complete set of statistical analysis of each coating profile. Anomalies and defects are quickly displayed and reported. Momentary undercoats, dross streaks, and strip coating flutter are some of the defects that we can detect and report.

Our Coat Weight System is available with several coil report options for quality reporting, production tonnage, zinc usage, and many others that are archived, displayed, recalled, and printed as desired.

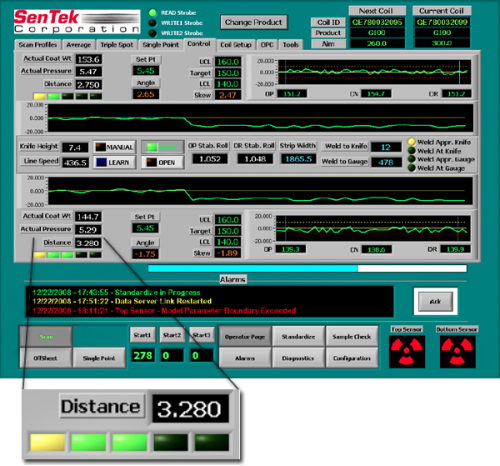

Coating Mass Control

A pressure and distance control for setting, tracking, and correcting coating mass based on preset variables and gauge feedback on air knife pairs at Hot Dip Galvanizing lines. The control system is a parametric algorithm with limited degrees of freedom for the air knife distance setup. Fine adjustment of coating mass is done continuously with air knife pressure, while air knife distance is maintained at the setting required for each control parameter group.

The control program features a LEARN mode (sometimes known as a “Shadow Mode”), where control action is displayed but not passed on to the air knife. In this mode the model compares the control action to the predicted results and sets up corrective coefficients that “teach” the model about any changed behavior in the process.