These training classes are held both at our customers’ plant sites and at SenTek’s facility in Columbus, Ohio. Our training classes are intended for the engineers, technicians, operators, electricians, and millwrights who install, operate, maintain, and calibrate X-ray and isotope gauges and scanners. These classes and seminars are set up as a modular system, where the customer can combine one or more modules to a training program that is most appropriate for their needs.

THK-101 Absorption Gauge Basics

This is a one-day class for thickness gauges that covers the following: Absorption curves, base calibration, alloy and product calibrations, Ion Chamber fundamentals, Electrometer and Detector circuitry, Standardize, sample check, and other program functions, and basic thickness gauge troubleshooting and maintenance.

THK-102 Beta and Gamma Gauge Training

This is a one-day class for thickness gauges that covers the following: beta and gamma sources, beta gauge geometry, flutter tuning, alignment and swing head principles, gamma gauge geometry, beta gauge calibration and accuracy challenges, gamma gauge calibration and accuracy challenges, and beta and gamma gauge troubleshooting.

THK-103 X-ray Gauge Training

This is a one-day class for thickness gauges that covers the following topics: X-ray tube principle, High-Voltage power supplies, X-ray gauge tuning, setup, and calibration, X-ray gauge geometry and maintenance, and X-ray gauge troubleshooting.

THK-201 Advanced Thickness Gauge Topics

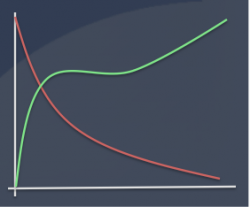

This is a one- or two-day class for the advanced gauge user or rolling mill engineer that can cover one or more of the following topics: Absorption Index and Chemistry Dependent Alloy Calibration, Sensor time constants, DAC rates, A/D rates, frequency response and analysis, sensor noise topics – statistical, electrical, process noise understanding, propagation delay and control tuning factors, vibration effects and mill-vs-gauge resonance, and mill and process troubleshooting using gauge data.

CWG-201 Advanced Coating Gauge Topics

This is a one- or two-day class for the advanced coating gauge user or coating line process engineer that can cover one or more of the following topics: X-ray fluorescence and coating chemistry, Sensor time constants, DAC rates, A/D rates, coating profile analysis, historical gauge data and SPC, propagation delay and control tuning factors, and strip flutter in the coating section.

RAD-100 Radiation Safety Basic Course

This is a one-day (six hour) class that can serve as an introductory course or a refresher course on radiation safety for fixed gauges. This class is intended for gauge device users, operators, and maintenance personnel. Topics typically include Biological Effects of Ionizing Radiation, Safe Operating Procedures, ALARA and minimizing exposure, Preventing Contamination, X-ray safety, Emergency Procedures, Security Requirements, and Access Control Programs.

RAD-200 Radiation Safety Extended Course

This is a one- or two-day class that includes the topics of RAD-100 and also includes service procedures such as source installation, source removal, leak testing, radiation patterns, shutter mechanisms, and safety features and mechanisms.

STK-101 Basic SenTek Gauge System Service and Maintenance

This is a one-day class for the SenTek 1000 or 500 systems that covers the following topics:

- System architecture

- Power supplies and circuit protection

- Wiring and cabling

- Interlocks and safety features

- Operator screens

- Maintenance and diagnostics screens

- System configuration and file archiving

- Reboot and re-start procedures

- Log-on and access control

This class is normally provided with the installation of a new SenTek system.

STK-102 Advanced SenTek Gauge System Service and Maintenance

This is a one- or two-day class for the SenTek 1000 or 500 systems that builds on the STK-101 class, and covers the following additional topics:

- Signal processing and board-level architecture

- Calibration table tuning and adjustment

- Common faults and advanced troubleshooting

- DAC set-up and tuning

- PC setup, rebuild, and replacement

- Other topics as necessary.